Organize the Health-Care Workplace with a Lean 6S Program

Posted on January 04, 2019

Updated: September 7, 2022

On a typical day, healthcare workers may have to deal with many stressful and urgent situations. The pandemic further impacted this situation, so much so that a review of healthcare professionals found a 23% prevalence of depression and anxiety and a 39% prevalence of insomnia during COVID-19.

Some of the routine tasks that healthcare workers conduct regularly include retrieving medicines, materials and supplies from storage rooms. Most often these rooms can get disorganized quickly and lead to immense wastage of time and resources.

Today, we’ll look at some of the consequences of disorganization and the best possible recommendation to help healthcare workers overcome it in their workplace.

Disorganization can lead to several other issues, including:

- Waste of time while searching for improperly stored items

- Safety issues resulting due to disordered spaces

- Lack of inventory management

- General fatigue and mental stress

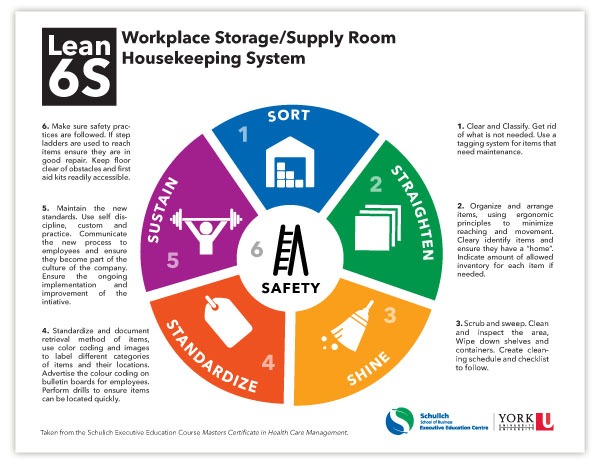

Lean 6S Program Can Help Organize the Healthcare Workplace

“Lean” refers to a business methodology that promotes continuous improvement in work practices and focuses on what adds value from the customer’s point of view. Lean 6S (otherwise known as 5S + Safety) approach helps to promote and sustain productivity and safety throughout a workspace.

A lean approach seeks to eliminate waste and reduce stress and frustration for workers — improvements that in turn benefit the customer experience.

“Lean is a way of thinking – not a list of things to do.” – Shigeo Shingo

Originally, the program was created to make factories more organized, efficient and safer. Now, it has evolved to have broader applications and can be implemented to improve housekeeping practices in health care workplaces where waste and inefficiency can be a problem.

When implemented, the Lean 6S step program results in benefits such as less stress for employees, fewer injuries and accidents, higher levels of productivity, and overall efficiency of time and effort.

This approach not only helps organizations promote efficient working environments but also establishes a sustainable culture of safety.

You may also be interested in: Becoming a Learning Organization Through the Five Disciplines

Transform Unorganized Spaces Into Models of Efficiency

Here is a brief synopsis of the six steps required to transform an unorganized medical storage room into a model of efficiency.

- 1. Sort: This is the first step in the 6s method. It reduces clutter and ensures that workers are able to locate items easily. Workers should start with clearing and classifying items and letting go of everything that is not useful. Workers often tag items “red” to denote that they are unnecessary and can be discarded. “Yellow” colour dictates that items can be stored off-site for future use.

- 2. Straighten: This process includes organizing all remaining items (besides those tagged red and yellow). In healthcare setups, workers use ergonomic principles to locate items to minimize reaching and movement. The objective is to identify items and ensure they have a “home”. Some useful tips include creating a visual workplace, and identifying the amount of inventory needed.

- 3. Shine: Once the unnecessary items are discarded, required items are stored, and all the necessary ones are organized, the workplace needs to be cleaned. Workers need to take preventive measures to ensure the area remains neat and tidy. Some of these tasks could be cleaning and inspecting the overall space, sweeping floors, wiping down shelves and containers, etc.

- 4. Standardize: Standardizing is the fourth step of the Lean 6S methodology. This step makes sure that workers adopt a new workplace norm by following best practices and creating routine procedures for the previous three stages. It aims to help all workers have the same work routine and develop more efficient work habits. Most organizations set visual reminders, set employee expectations and conduct regular inspections to keep things on track.

- 5. Sustain: This is one of the most challenging steps of the 6S method. It includes making sure that the processes set in place are followed and applied consistently for an extended period of time. Workers are encouraged to practice self-discipline and provide suggestions to guide how processes can improve over time.

- 6. Safety: The final step focuses on identifying hazards and carving preventive controls to keep workers safe during operational hours and on the premises. It also ensures that safety compliance is met and all necessary protocols are followed.

Integrate Improved Methodologies with Schulich ExedEd’s Lean 6S Program

Getting organized is the best way to streamline work and help your workers get the most out of their day. Our Masters Certificate in Healthcare Management program is designed to help workers in the healthcare sector meet the challenges to deliver better care and lead people more effectively.

Schulich ExecEd provides academic advising to help you identify resources and support for your program. To learn more about program information and program requirements, contact an advisor today.